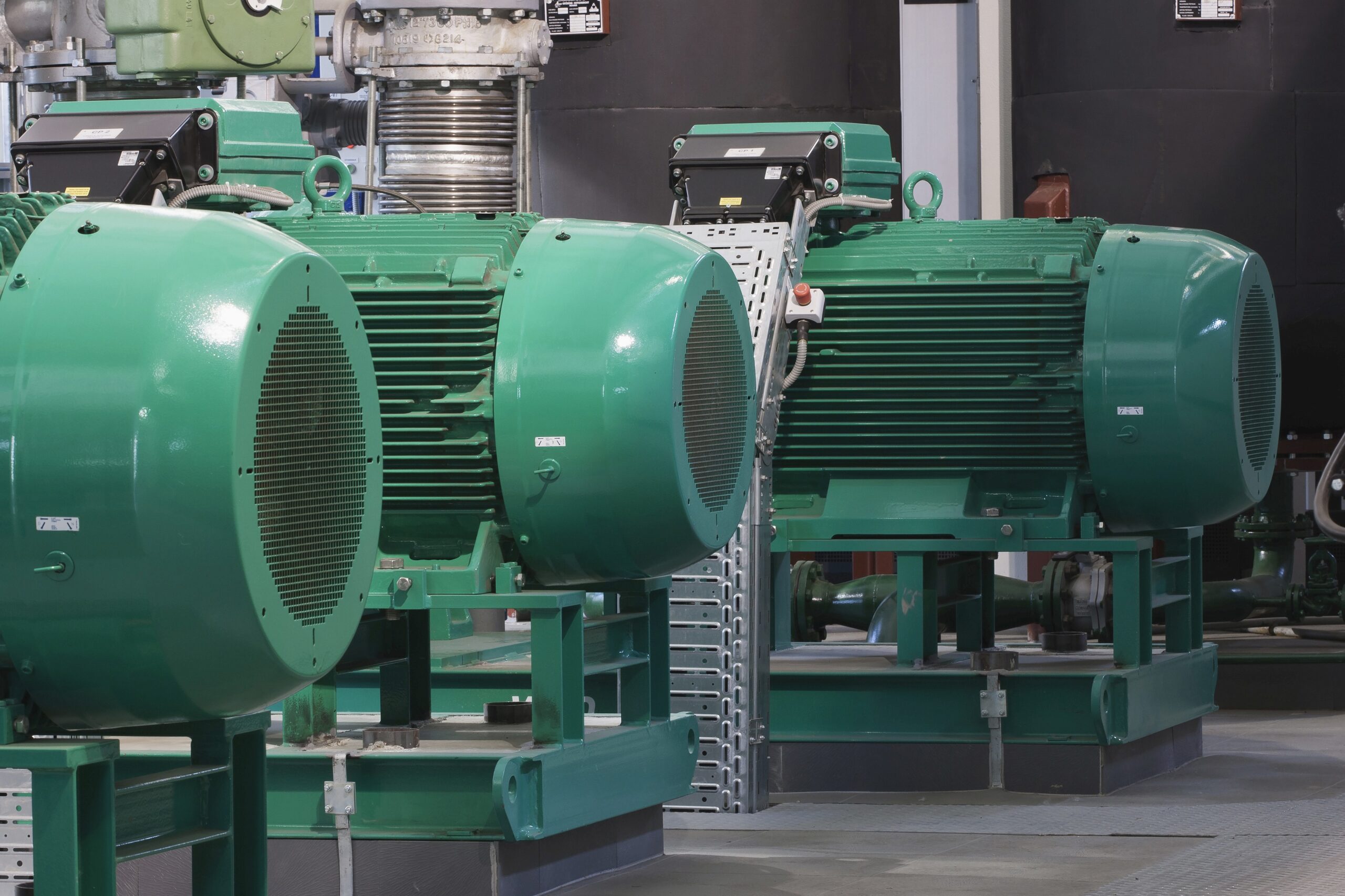

AI-driven condition monitoring of electric motors

Samotics produces SAM4 (Smart Asset Monitoring 4), a system that monitors the condition of electric motors. The unique feature of SAM4 is its technology: the system monitors electric motors by continuously measuring the power and voltage on the motors. Technolution Perform developed the sensors that supply SAM4 with measurement data.

A unique system with operational advantages

Condition monitoring of electric motors is traditionally done by measuring the vibrations of the motor using a vibration sensor mounted onto the motor. But environmental conditions such as humidity and dust have a detrimental impact on the vibration sensors. Technolution Perform’s sensors measure power and voltage, and there is no need therefore for them to be mounted directly onto the motor. The sensors are placed in control boxes, where they are protected from external influences. Additionally, the SAM4 system provides more information than the vibration sensors can: it also gives insight into operating hours, energy consumption and stress on the motors. The condition monitoring it provides is very advanced and can predict failures of the electric motors with a high degree of accuracy. This means unexpected outages and superfluous maintenance are almost entirely a thing of the past.

Artificial intelligence

Technolution Perform has developed the Atolle sensors in close cooperation with Samotics. The sensors measure the power and voltage in the electric motors with high frequency and precision. The data is transmitted with high bandwidth to the dashboard at Samotics, and the data is then analyzed with the help of AI algorithms. SAM4 gives the user exhaustive insight into the condition of his electric motors.