Signal Integrity and Power Integrity for High-Speed Systems

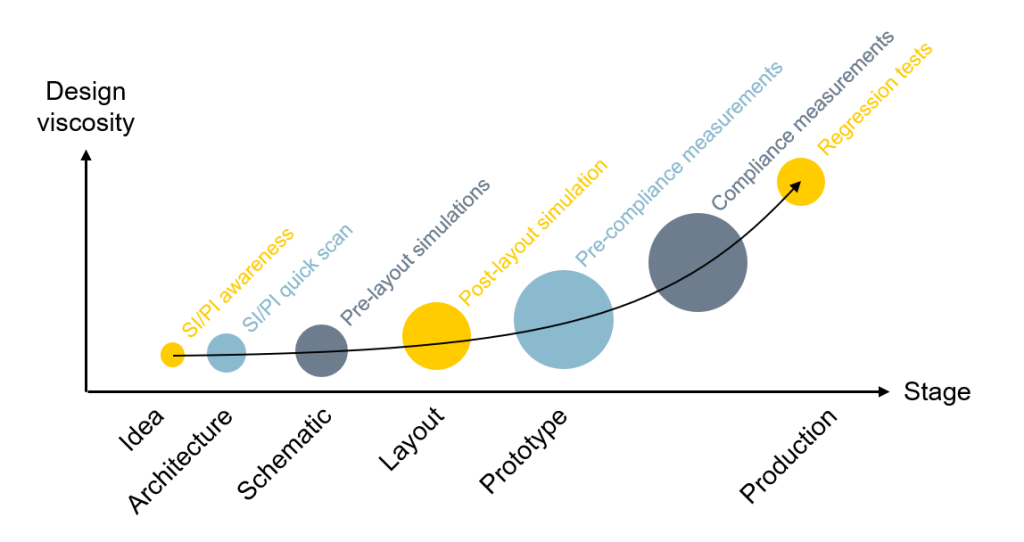

Are you developing an electronics product which has data connection speeds of multi-gigabit per second? Or are you redesigning an old megabit-per-second product with modern-day ICs? Then it is important to give due attention to signal integrity and power integrity (SI and PI) during every stage of the development process. This will help prevent issues that can cause components to behave in unexpected ways, such as erroneous timing of signals on interfaces or inadequately dimensioned power supplies. Another crucial aspect to consider is compliance with interface standards. The sooner you start thinking about SI/PI the better, because adjusting your design is much harder in the later stages of development.

Technolution Advance can assist you with SI/PI in many ways, such as:

- Identifying which parts in your design are critical for SI/PI

- Determining the main contributors to possible SI/PI issues in a design

- Helping you find a cost-effective and reliable approach to SI/PI issues in your design/application

- Performing compliance simulations and measurements for all bus standards (USB3, PCI Express, HDMI, …)

There are many different things to consider in the different stages of a development process. We have listed a few important consideration ones below.

Idea stage – Awareness of Signal Integrity and Power Integrity

Always remember: all digital signals are actually analog voltages and currents. Every data connection begins and ends with an electrical signal. This is why you should always factor in SI/PI issues if you are aiming for high data speeds (like DDR, USB3, PCIe). Even in the very first stage of generating ideas. What will the rise and fall times of your electrical signals be? What bus standards does your system need to comply with? What SI/PI issues are you likely to encounter? Need to catch up? Watch the 30-minutes Fast & Flawless webinar today and discuss it with your team.

Architecture stage – Quick scan of SI/PI issues

Knowledge is everything when you are dealing with SI/PI. If you know what you are looking for, it is possible to identify SI/PI challenges in a block diagram of the system. Even when you are in the early stage of converting your ideas into an architecture, there are certain questions that need to be asked to verify that you are on the right path, without losing sight of recurring costs and reliability. But determining SI/PI bottlenecks in an architecture destined for high data speeds can be really complicated. That is why we offer a quick scan service. Our consultant will come on site to understand your context, architecture and existing SI/PI skills. Based on this visit, we will draw up an SI/PI plan. This plan details when you should take what action, and gives you an estimate of the required time and budget. Need a quick scan? Contact Technolution today to discuss the possibilities.

Schematic stage – Pre-layout simulations

Once you have a plan for the general implementation of your high-speed system, you can start testing SI/PI by simulating parts of your design. Technolution Advance uses sophisticated simulation tools, such as Advanced Design System (ADS), which provide an integrated design and simulation environment for electronics designers. Using these tools, we will create realistic pre-layout simulations of parts of your design to define stack-up and design rules for your critical signals. We will also include production tolerances to guarantee a reliable product over multi-batch volumes. With the simulations in hand, we can determine which elements of the design are most likely to cause SI/PI problems.

Layout stage – Post-layout simulations

Once the layout for your high-speed system is complete, but before you build the first prototype, it is time to make a final assessment of your signal’s vulnerability to reflections and loss and to crosstalk from adjacent connections. We can verify compliance with interface standards using specialized ADS test benches. This will produce a layout verification report with a verdict: will this work? And if not, what modifications are required before you manufacture the first prototype?

Prototype stage – Pre-compliance measurements

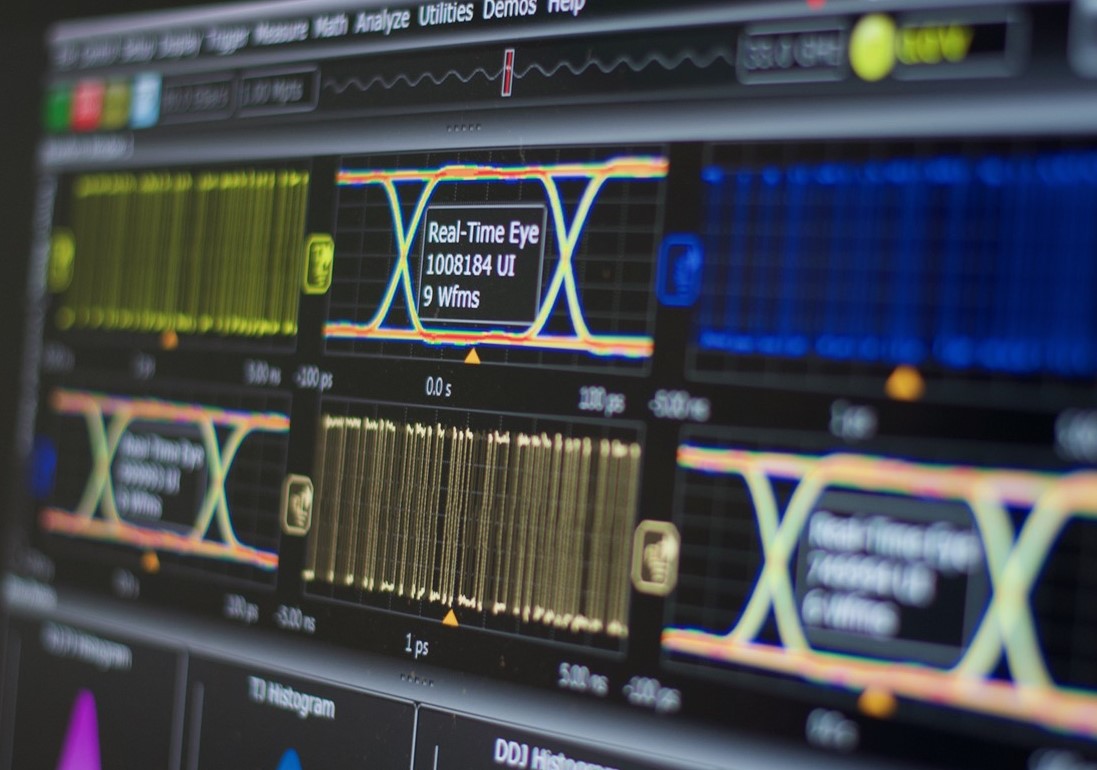

Now that the prototype of your new product is built, you have entered the final stages of the development process. The time for major changes to the layout has passed. Before you submit your system to formal compliance tests, you need to verify quickly that all inputs and outputs comply with the standards, for example using in-situ probing. There is no need to purchase expensive compliance testing equipment. Technolution Advance has the equipment to perform these measurements for you. If hardware and/or software modifications are necessary, we will work together with you to identify and efficiently implement these changes. Depending on the required modifications, another prototyping cycle may be necessary.

Prototype stage – Compliance measurements

To prove that the final prototype is compliant with interface standards and regulatory requirements, you need to carry out certain compliance measurements. Depending on the interfaces, Technolution can do this for you or ask a specialized testing center instead. In either case, you will receive a formal compliance report.

Production stage – Regression tests

Some changes may be necessary during the lifecycle of your product. These can be minor, for example changes due to a shortage of certain components. But they can also be major, for instance if you want to add new functionality and improve performance. In either case, regression tests are needed to demonstrate that compliance with standard and functionality has been untouched by the changes. Technolution Advance can help you by selecting the relevant tests, performing them and drawing up the reports.

Let’s talk about Signal Integrity and Power Integrity

And find out how we can help you