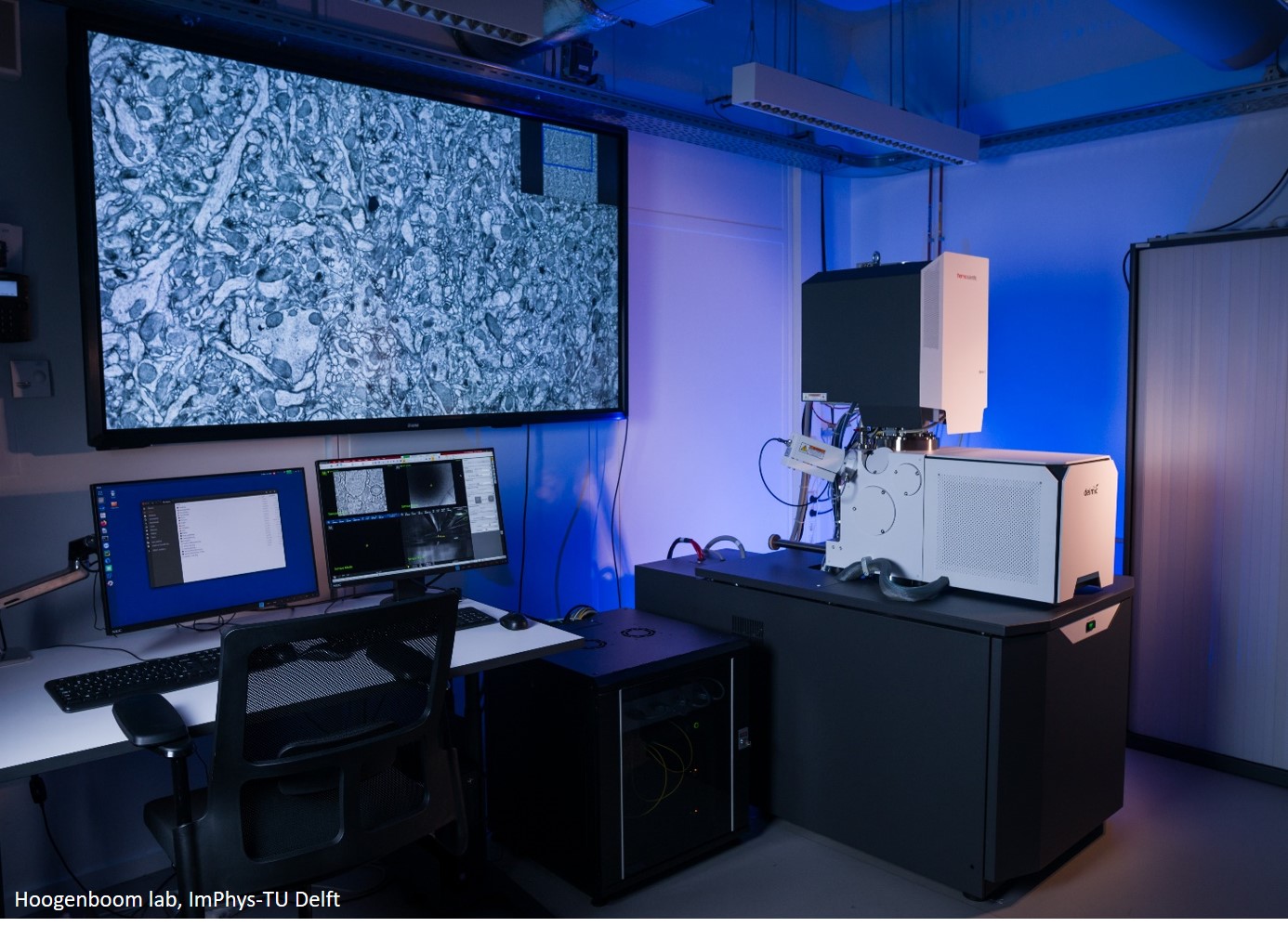

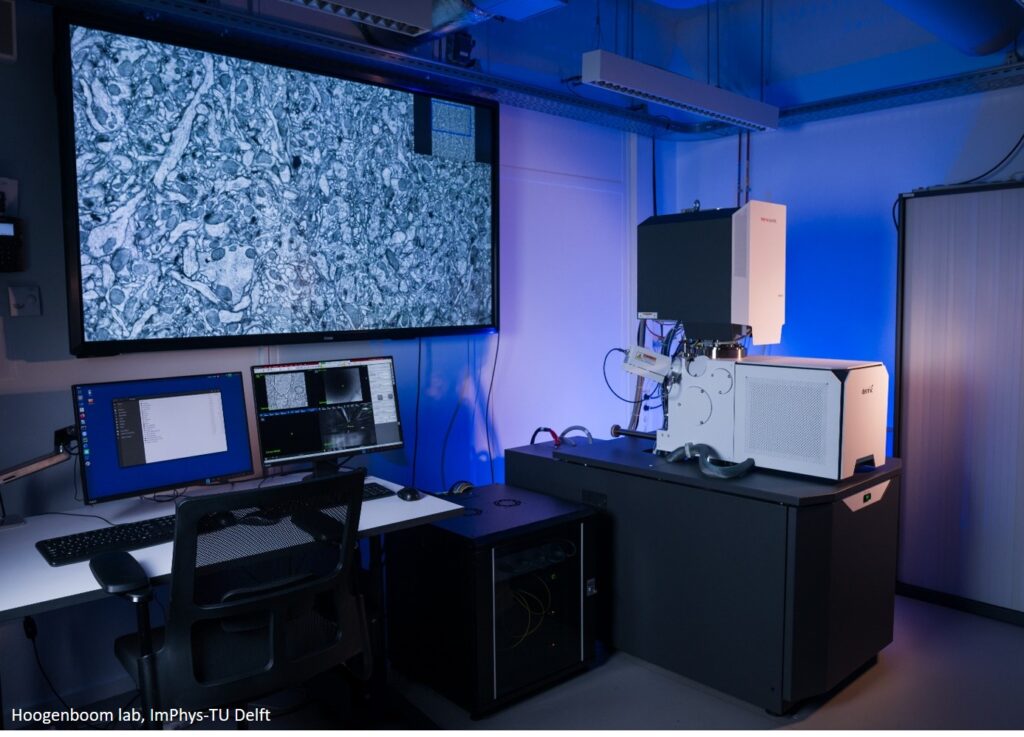

Fast multibeam electron microscope offers new possibilities

The Fast-EM electron microscope is a hundred times faster than a regular scanning electron microscope. Its secret is that the Fast-EM uses not one electron beam to scan, but 64 beams simultaneously. The device marks a revolution in science and the medical world. But the Fast-EM is only one link in a bigger chain. Higher scanning speeds require new technology, to facilitate both the input of samples and the output and storage of scanning data.

Scientists and doctors like to have as detailed a view of the world as possible. Electron microscopes have a resolution that is measured in nanometers, only a little bigger than the smallest atoms and molecules. To give you an idea: an O2 oxygen molecule is approximately 0.3 nm large. This means that electron scans offer an unprecedentedly detailed view of reality.

Regular scanning electron microscopes or SEMs have one important drawback: it takes a lot of time, sometimes days or weeks, to scan a sample using a single electron beam. The time required increases exponentially when the scan is a 3D scan, made up of multiple 2D scans of a sample that has been carved up into extremely fine slices. In practice, the time required for a 3D scan is unfeasibly long, particularly for medical situations where time is of the essence. Moreover, scanning time is expensive.

The Fast-EM, which was developed by a consortium made up of Delmic, Technolution Advance, Thermo Fisher Scientific and TU Delft, solves many of these problems due to its much higher scanning speed, which it has thanks to its multibeam technology that uses 64 electron beams. The Fast-EM can perform a scanning task in fifteen minutes that would take a SEM a day to complete. The Fast-EM makes much more efficient use of time and money, and this has opened the door to new applications, for example 3D scans for medical examinations. The developers of are now working hard to make this possible.

A conveyor belt for 3D samples

The Fast-EM is currently being used by two early adopters, the TU Delft and the Universitair Medisch Centrum Groningen (UMCG, Groningen University Medical Center). The multibeam technology is working and users are reporting excellent results. The Fast-EM does still require specialized operators who have to deal with the complexity of manually preparing the samples and feeding them into the machine, as well as the with stream of scan data that is generated at a speed of 10 Gbit per second. To optimally leverage the Fast-EM’s speed, the consortium is developing automated solutions, both for the preparation and input of samples and for processing the data streams.

A 3D scan of a sample is made up of a stacked series of thousands of 2D scans. If the 3D scanning process is to be smooth and fast, it therefore needs a kind of conveyor belt. At the moment, the process of feeding samples into the device is largely manual. The sample to be scanned is chemically processed and cut into razor-thin slices using a diamond knife. Several hundreds of these slices are then placed onto a so-called scintillator. Once the position of the slices on the scintillator and the desired scanning sequence have been indicated, the system is ready to scan. The 2D scanning data from each scan is then combined to form a 3D image of the sample. The consortium is now working to automate this complex 3D scanning process as much as possible for the final market version of the Fast-EM. And Delmic is working on a cutting robot and a solution that will be able to present nine scintillators to the Fast-EM at once.

Smart data acquisition

In addition to the input of samples, another challenge is processing the immense and continuous flow of scanning data. No platforms are currently available for this. The solution will have to come from new technology for high-speed data. Technolution, which also developed the Fast-EM’s electron camera, is currently building a data acquisition platform that will be able to process the scanner’s data flows in real time. The platform will be fitted with software and firmware that pre-process the data during the acquisition phase, so as to visualize the scanning information and minimize the required storage space.

This will allow users to navigate the data more quickly and easily and to access the information. The new data platform will be unique because its main feature will be that is able to rapidly and continuously process the streaming data. This is no mean challenge. Despite the Fast-EM’s high speed, a 3D scan often still takes multiple days, and at a data speed of 10 Gb/s, the required storage space fills up quickly. It is just not feasible to store all the petabytes of raw scanning data. Techolution will therefore be equipping the data platform with intelligence that is able to make justified choices.

Medical Google Maps

While the consortium is expanding and perfecting the technology of the Fast-EM, the early adopters are working on new applications for the fast electron microscope. UMCG’s ideal is to have a kind of medical Google Maps: an atlas of the human body that makes it easy to detect the characteristic features and striking aspects of specific medical samples. The center has a sterling reputation in the field of electron microscopy in life sciences (nanotomy), and UMCG researchers are making specific tissue data available on nanotomy.org. They are the world’s No. 1 in the field of nanotomy.

The electron microscope’s acquisition time has so far always been a limiting factor for research at UMCG. But Fast-EM is helping UMCG to further strengthen its profile as a center for data acquisition. One important condition for the solution is that it needs to get to grips with the avalanche of data – this is a big priority for the Fast-EM development consortium.

Zebrafish brains

TU Delft is supporting research of how brains work and of the causes of brain disease. Only electron microscopy can offer the resolution required to image connections between individual neurons. The brains of zebrafish are a perfect model for this kind of research, but even the minuscule brains of this fish would cost many years to scan using a regular electron microscope. The Fast-EM reduces this process to about a month. Technolution’s new data acquisition platform will make it possible to create a three-dimensional image of a zebrafish brain.

TU Delft also has a cutting robot developed by Delmic. The great challenge there is reconstructing 3D images from the individual 2D images. Because every slice may be slightly deformed, the software required is very complex. The applicability of the concept has now been established.

Lastly, the Delft university is building up experience with the use of artificial intelligence to recognize biological structures in scans. This is a complicated process because electron microscopy only generates grayscale, but AI is yielding excellent results.

A deluge of insights and ideas

The full range of possible applications of the Fast-EM is far from clear yet, but the consortium expects that rapid multibeam technology will open the floodgates to a deluge of new insights and ideas. Once it becomes an instrument in the hands of creative users, the Fast-EM will produce a true treasure trove of valuable visual data.

The multibeam technology of the Fast-EM

The Fast-EM can reach such high scanning speeds because it uses a fixed grid of eight by eight electron beams. Every individual electron beam scans a 64th part of the image. A corresponding sensor transforms the information from each beam into a grayscale for every scanning position, or a pixel. Once the scan is complete, this results in 64 tiles of 800 by 800 pixels. These tiles are then combined in real time to form an image of 6400 by 6400 pixels, called a singlefield. The sample stage is then moved to scan the next piece of the preparation. By permitting a small overlap between the scans, all singlefield images can be combined into a megafield image. A total image can in principle be as large as the entire sample holder, approximately 2 by 2 centimeters, but in practice the slices to be scanned usually have a surface of 1 square millimeter, that is, some 250,000 by 250,000 pixels, or 63 gigapixels per megafield. A 3D stack of a preparation will typically contain thousands of these slices. The Fast-EM was partly realized by a contribution from the European Regional Development Fund ERDF and is part-financed in the context of the European Union’s response to the Covid-19 pandemic.

Award winning Technology